Microtubes

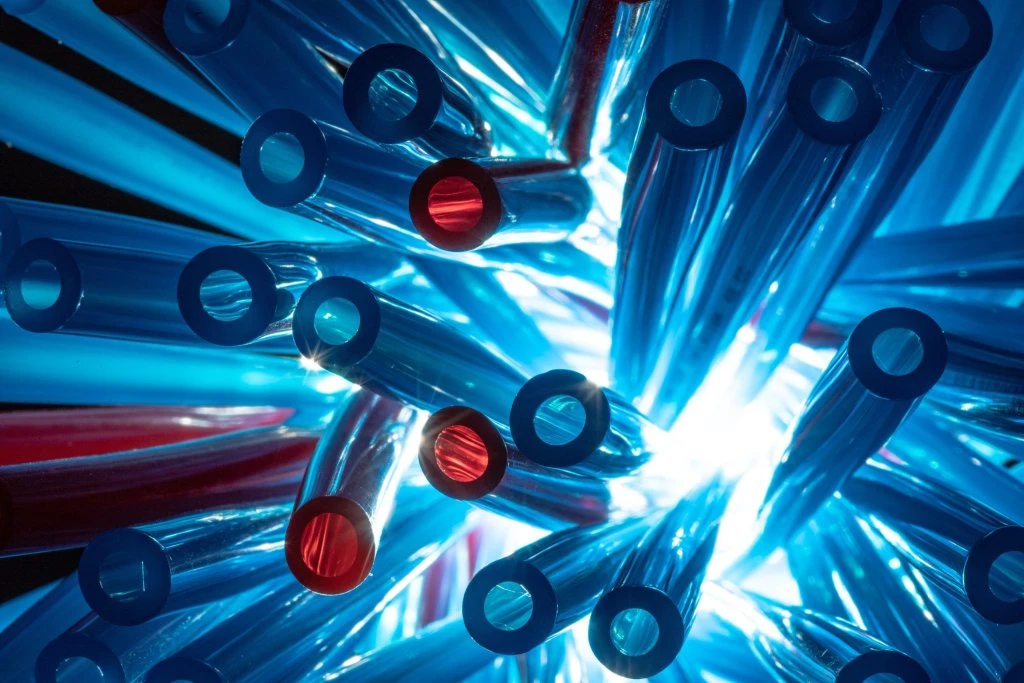

The expertise from which ENKI was born lies in the extrusion of plastic microtubes in a cleanroom environment, primarily for medical use, but not exclusively.

Our production flexibility allows for both large-scale production orders and small-scale prototype productions.

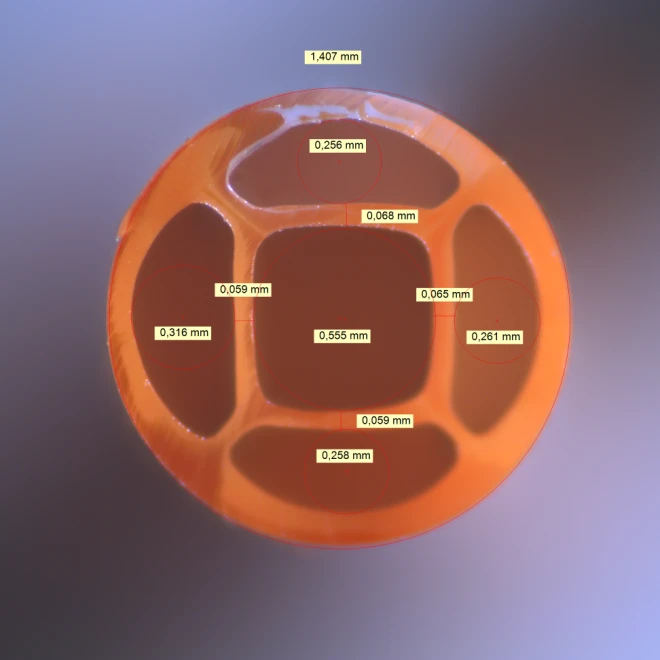

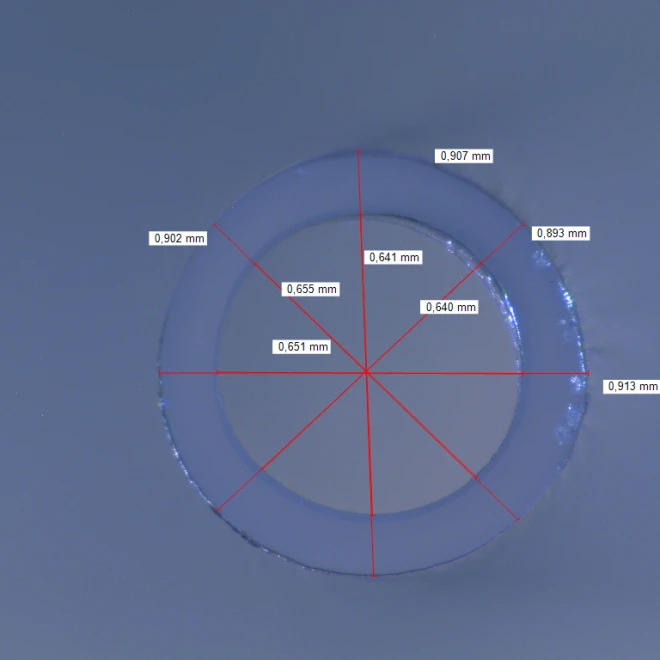

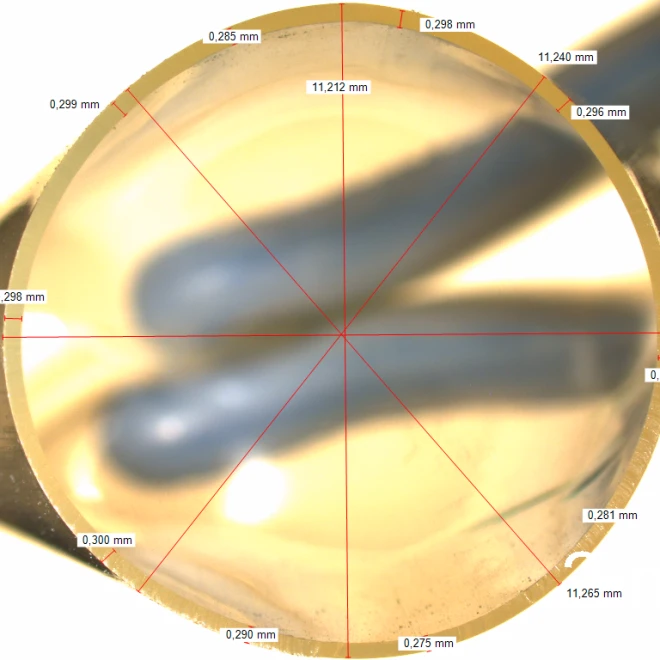

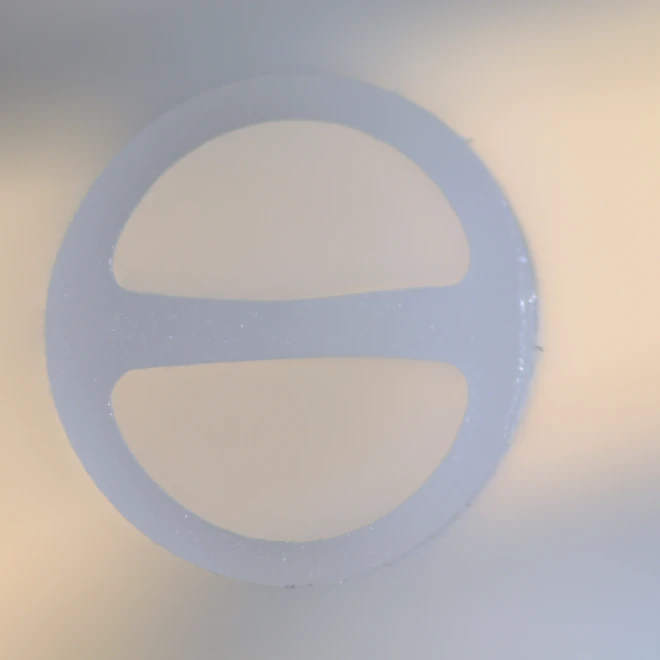

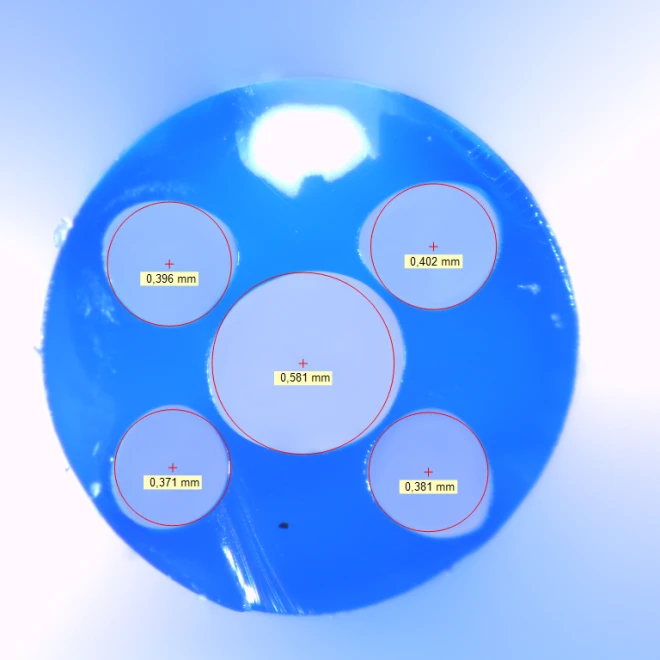

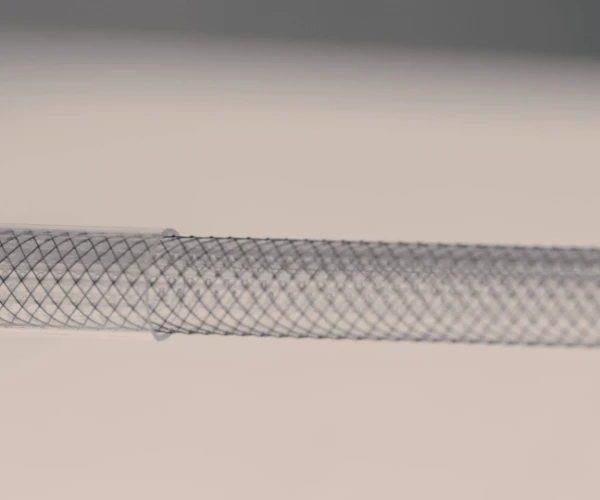

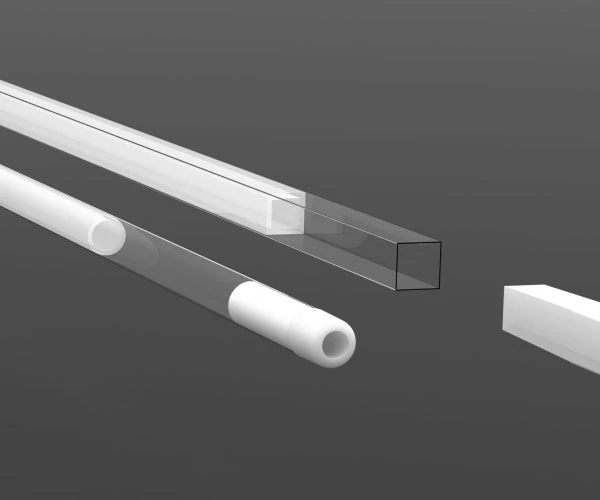

With two three-layer extrusion lines and a high level of expertise, we can extrude multilayer and multilumen tubes with dimensions ranging from 0.2 to 14 mm and tight tolerances, up to ±0.02 mm, depending on the materials used. These tubes can have various features, including tapered, splittable, modular, and radiopaque configurations.

ENKI has extensive experience in extruding over 150 plastic materials, ensuring optimal solutions for various applications.

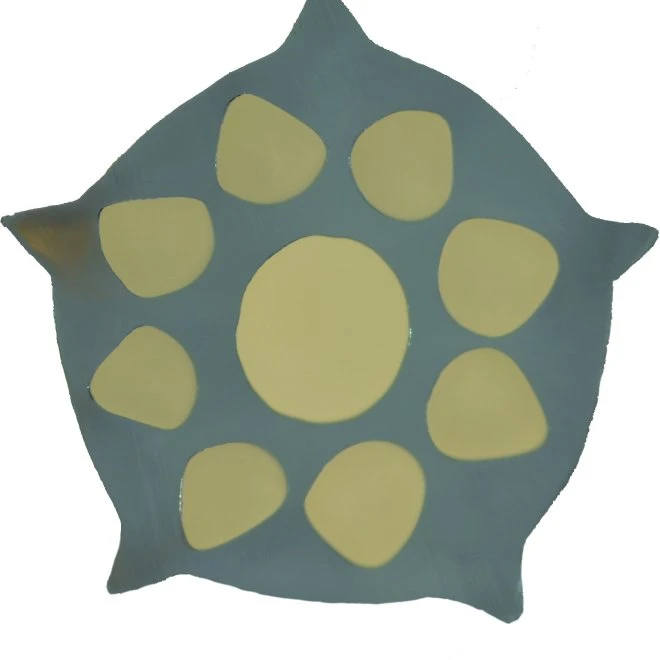

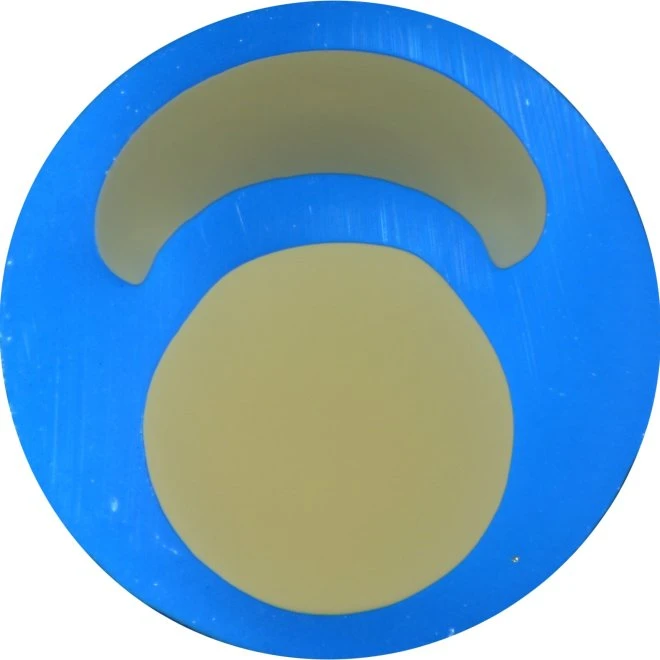

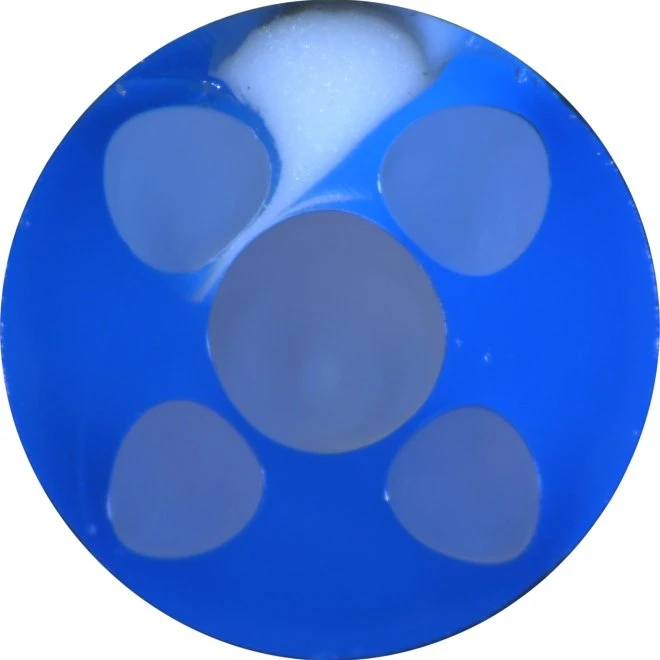

Single-lumen, multi-lumen, multilayer, with colored or radiopaque stripes, splittable, tapered, transparent, or colored, the microtubes designed and produced by ENKI are the ideal solution for the most technologically advanced catheters.

The small dimensions of ENKI's multilumen tubes allow for the design of minimally invasive medical catheters without compromising the required functionality of the application.

ENKI will propose the most suitable solutions to its clients on a case-by-case basis, balancing manufacturability, cost, and performance.

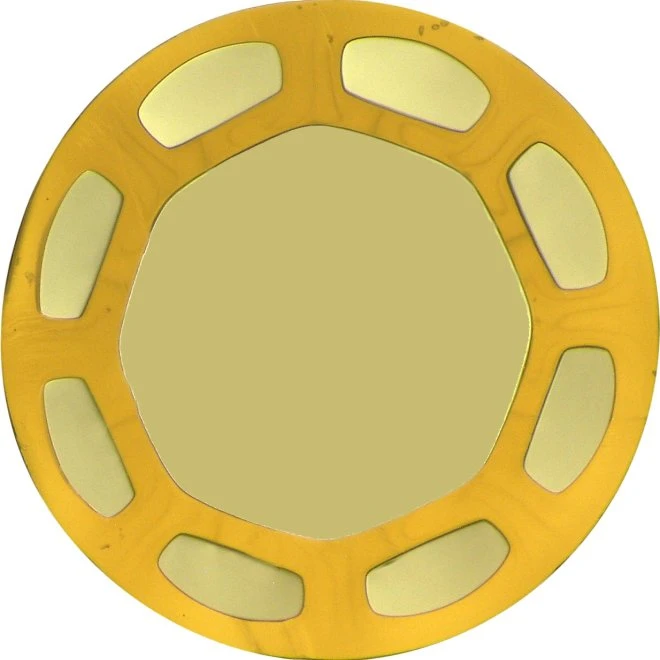

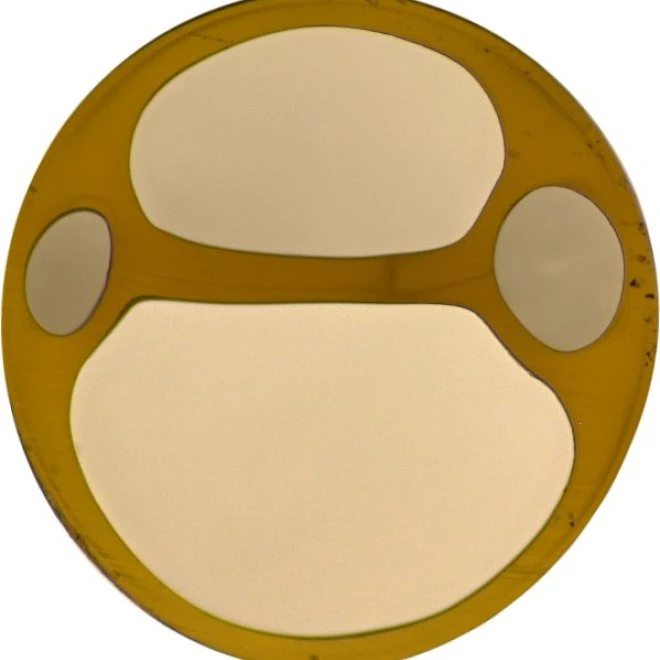

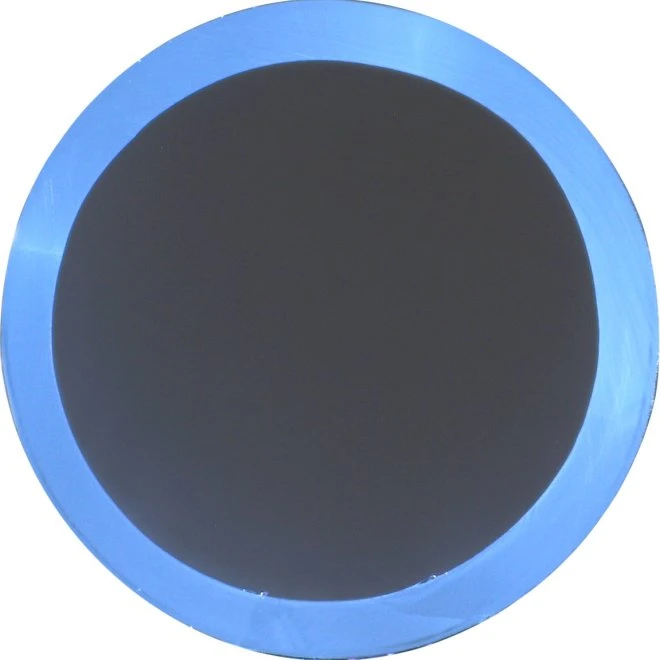

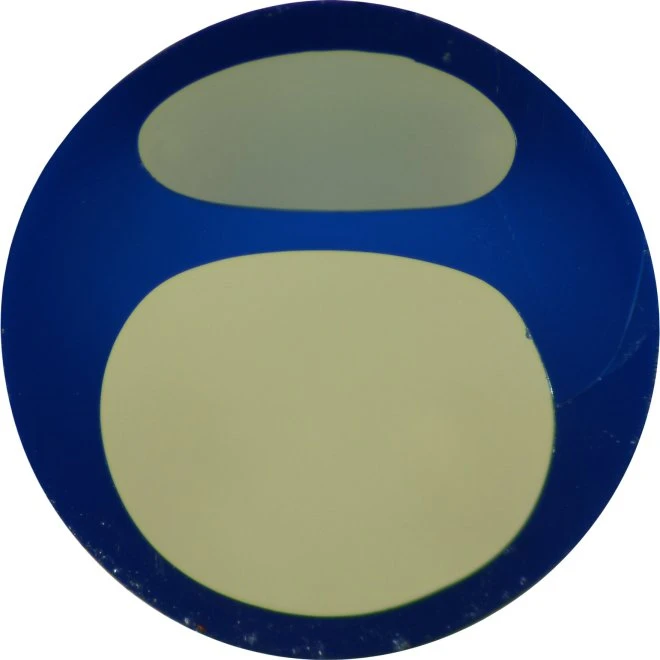

In the gallery below, there are some microscope sections

of microtubes and thermoplastic profiles designed and produced by ENKI.